DAIRY

Production

The production stages

Milk

The starting ingredient is the milk, which is produced entirely by our cows. After resting all night in large vats, the milk from the previous evening’s milking is mixed with the morning’s milk as soon as it has arrived from the barns in the traditional copper vats. To this is added calf rennet and whey, rich in natural milk enzymes obtained from the previous day’s processing. The milk is heated until it reaches the right temperature of around 30°C.

Curd

A few minutes after adding the rennet the first transformation happens. The milk coagulates in ten minutes or so. When the cheesemaker, with his expert hands, judges that the mass has reached the ideal consistency, he breaks up the curd that has been made in this way into tiny granules using an ancient tool called the “spino” (a type of very large whisk). This is when the flame comes on the scene in order to get a cooking temperature of 55°C, at the end of which the cheesy granules sink to the bottom of the vat forming a single mass.

Mold (“Fascera”)

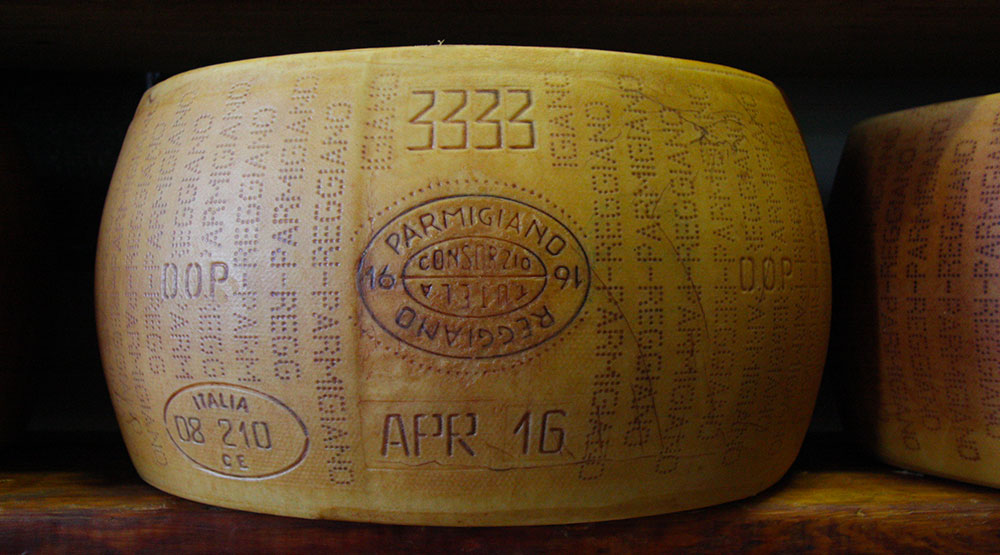

After about 50 minutes the cheesemaker gathers the cheesy mass and divides it into two parts called the “twins”, which are patted together and turned into a muslin sheet. The twins are left hanging on a pole across the vat and are then transferred into the "fascera" which will give the cheese its definitive wheel shape. Each wheel is now marked with an individually numbered casein plate, which will clearly identify it throughout the traceability chain. The wheel gets its marking that shows the name "Parmigiano-Reggiano", the month and year of production, and the number 3333 identifying our dairy. Space is left for the Consortium’s brand mark, which will be put on after 12 months when an expert inspects it using a hammer.

Salting

When the fresh Parmigiano Reggiano has taken on its characteristic wheel shape, the next stage is the salting process: the wheels are immersed in brine in special bathtubs to get them to absorb the salt completely naturally. The process lasts around a month.

Maturing

The wheels are left to rest on wooden tables for different times depending on the maturation, which ranges from 12 to over 50 months. The younger, clear-coloured cheese dries out and over time forms a darker-coloured rind.

Inspections and Marking

During maturation the wheels of Parmigiano Reggiano are rotated and brushed regularly. After 12 months have passed they are inspected by specialists from the Consortium. With firm hammer blows they assess whether or not there are cavities within the wheels. This ancient operation is called “beating” and is extremely difficult: only an expert technician is able to “listen to” dozens of wheels in the space of an hour. Once all the established inspections have been passed, each wheel receives the heat-applied brand of the Parmigiano-Reggiano Consortium that certifies the product’s absolute compliance with the production regulations.

Our Certifications